English summary

Development of national reserves of potash salts in Russia began in the 1920s. The first exploration brigade near Solikamsk in 1927 after one and half a year of the work has found out that potash salt reserves are huge and they are located closer to the ground surface than in Germany and France. Development of Verkhnekamskoye potash salt deposit began. Mines in the region of Solikamsk and Berezniki were constructed. Ore dressing factories were constructed. A group Soyuzkaliy was established.

Exactly in this period the Salt laboratory of the Academy of Sciences of USSR was created in Leningrad (1931) from which establishment the present VNII Galurgii JSC traces its history. The laboratory set a task to study salt resources of USSR using methods of applied geochemistry and physical-chemical methods. Also in this period training of potash specialists began. Halurgy began to be considered as an applied science specialized on natural salt processing. USSR became independent from the import of potash salts. Export of soviet potash started.

In 1934 the government declared on the creation of potash industry in USSR. In 1935 the Salt laboratory of the Academy of Sciences of USSR was transferred to the system of People’s Commissariat for heavy industry and reorganized into All-Union institute of halurgy (VIG). The institute began to deal with Solikamsk potash deposit, started developing plans of salt industry development. In 1937 potash theme became a leading theme in the institute’s research works. VNIIG was transferred under control of Soyuzkhimprom. In the middle of the 1930s the institute’s scientists began to work on creation of production process of magnesium metal which was very important for national economy and defense.

In the period of the Great Patriotic War main institute’s divisions in 1941 were evacuated to the regions of location of raw materials sources of halurgy production where 5 stationary groups were created which performed technological support for active production facilities:

- Solikamsko-Bereznikovskaya;

- Karabogazskaya;

- Inderskaya;

- Zapadno-Sibirskaya;

- Redneasiatskaya.

In besieged Leningrad the institute produced medicines for people and the army of Leningrad front. Personnel worked in hard blockade conditions.

The year of 1945 was the year of the institute’s recovery, first of all the collection of the workers separated in the war period.

After the war potash industry of USSR developed rapidly. In this period the institute performed large volume of works on feasibility study, estimation of reserves, development of processes for ore mining and dressing, design of mining-chemical enterprises of Russia, Republic of Belarus, the Ukraine. At the end of the 1940s — first half of the 1950s VNIIG created the projects of recovery and reconstruction of Stebnikovskiy potash plant and Kalushskiy chemical-metallurgical plant in the Ukraine. The institute developed a project of construction of the chemical plant in the First Berezniki potash plant.

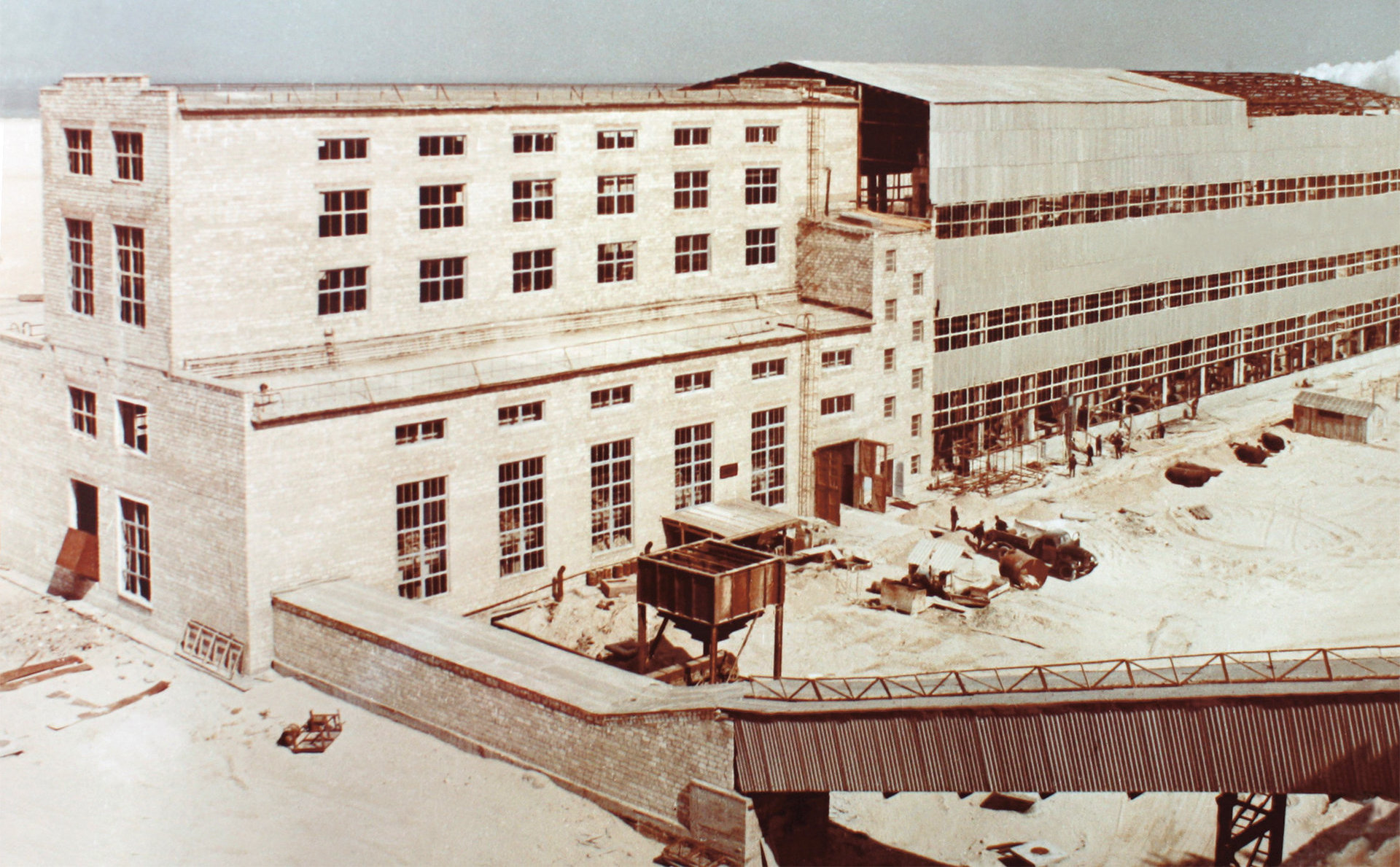

In the 1960s based on the research and design works of VNII Galurgii, by the active participation of the Ural specialists, reconstruction and expansion of the First Solikamsk potash plant were performed. In 1967 as a result of incorporation of VIG and the institute’s Leningrad branch Gosgorkhimproekt a complex All-Union research and design institute of halurgy was established.

In order to improve and increase efficiency of research and development works that were carried out directly in potash objects the research laboratories were organized: Bereznikovskaya (1957), Soligorskaya (1961) and Kalushskaya (1959). On their basis in 1971–1972 branches were created in Perm, Minsk and Kalush later transformed into independent institutes. Research laboratories were also organized in the village Stebnik (L’vov region) and the village Bekdash (Turkmenia).

In the 1950s–1960s for the first time in USSR the institute began studies for developing fundamentals on salt flotation and flotation technologies of potash ores of different composition. It enabled to build in a short time 9 flotation objects since 1963 till 1983 in the Ural, in Belarus and the Ukraine. It provided an intensive development of potash fertilizer production in the Soviet Union.

The institute’s specialists studied composition and properties of salt solutions, technologies of obtaining and processing sedimentary salts. The scientists developed halurgic, flotation and electrostatic methods of processing potash and potash-magnesium ores of chloride and sulphate types. The institute’s specialists developed and implemented a method of underground leaching and processing the obtained solutions.

Scientific work of the institute laid a basis for success of the country’s potash industry. As a result of the large-scale construction of large potash enterprises in 1968 the national potash industry took the world’s first rank on the volume of potash fertilizer production and was taking this position until collapse of the USSR.

In the 1970s the Second Solikamsk potash plant (1973) and the Fourth Soligorsk potash mine (1979), and in the 1980s the Third Solikamsk potash plant (1983) and the Fourth Berezniki potash plant (1987) were put into operation.

VNII Galurgii takes a leading role in scientific justification of many new technical and technological solutions which were realized in the industry enterprises. The institute and its branches have developed processes of underground mining of potash and potashmagnesium ores based on the research of physical and mechanical properties of salt rocks, mechanical breaking and transportation of ores of different composition, principles of their cutting. The issues have been solved on opening, preparation of new mine sites, support of mining workings, backfill of mined out areas with solid and liquid production waste, prevention of gas-dynamic phenomena etc.

In VNIIG laboratories rational equipment packages of miner systems were for the first time substantiated which are at present widely used in the Ural region and in Belarus, efficient types and parameters of their elements — miners type PK and Ural, соnveyor hoppers and self-propelled cars.

As a result of research and development works performed by VNIIG together with PO Belaruskali in the mine of the First mine group in 1969–1970 a room-and-pillar method with smooth roof-lowering on flexible pillars was implemented, and in the mine of the Third mine group in 1971–1973 a long-pillar method with separate mining of sylvinite with hydraulic complexes and roof collapse was implemented. Application of new progressive methods of potash ore mining with little losses enabled to increase the extraction of salt reserves 1. 5 times and thereby prolong the operation period of Starobinskoye deposit.

As a result of successfully performed modernization of the Ural and Belarus mines the potash industry became for 10 years the most mechanized mining industry of the country. Besides the volume of ore production increased in comparison to 1960 more than 10 times, reaching in1988 the highest value — more than 80 million tons. The specialists of VNIIG have contributed a lot into solving the problems of rock geomechanics and safe operation of potash mines, their protection against flooding, protection of the undermined surface objects (Berezniki-Solikamsk industrial region; Soligorsk). Herewith one of the priority research directions of VNIIG was detection and forecasting of abnormal structure of the rocks of waterproof formation of Verkhnekamskoye deposit.

Participating in the works on technical modernization of current potash enterprises and creation of new ones the institute’s employees have offered new types of technological equipment for halurgic processing of sylvinite and carnallite ores, have developed technologies of adjustable vacuum-crystallization of potassium chloride with obtaining 95–99% KCl and dressed carnallite with improved granulometric composition.

The institute has developed processes and reagent schemes of flotation processing of potash ore with KCl content and silicate-carbonate and sulfate water-insoluble additives in a wide range of values, providing production of muriate of potash with chemical composition and physical-mechanical properties in accordance with the requirements of the world market at the extraction of KCl into finished product up to 92–93%.

Under supervision and with direct involvement of the institute’s specialists the equipment and process schemes of densification and dewatering of the products of ore processing, drying of potash crystallizer and flotation concentrates in the fluid-bed furnaces, granulation of finished products were developed.

A considerable contribution of VNII Galurgii specialists into the development of national salt, sulfate and phosphate industry is generally recognized. Under the institute’s projects: Mozyrsalt OJSC producing «Extra» salt (Belarus), salt mine Nr. 4 of the State enterprise Artyomsol (Soledar, Ukraine), one of the biggest in the world — Baskunchakskiy salt industry and Yar-Bishkadakskiy brine field (Bashkortostan), sulphate enterprises — Karabogazsul’fat (Turkmenia) and Kuchuksulphate (Altai Territory), Kingiseppskiy ore dressing phosphate complex and others have been built and operate successfully.

The developments of VNIIG enabled to improve considerably physical-mechanical properties of fine-grained and granular КСL (granulometric composition, caking ability, flaking etc.). It allowed to compete with products of the world’s potash producers and export muriate of potash from Russia and Belarus to more than 60 countries.

In 1972 branches of the institute were established: Kalush branch (Ukraine), Belarus branch and Ural branch in Perm.

By 1978 the Ural branch became the main designer of the mines of production enterprise Uralkali. By decision of The Ministry of chemical industry the institute became an authorized general designer of all the active mines of production enterprise Uralkali.

Since 1980 the institute performed the whole complex of design works. Under the projects of the institute’s branch formed in Perm for the first time in domestic practice high-altitude waste storage up to 100 metres high, objects of interdepartment transport, construction of the main underground fan installation and other important production facilities were realized.

In 1983 for the first time in the domestic and the world practice a combined machine technology of carnallite seam mining was implemented which was dangerous on gasdynamic events.

Specialists of the laboratory on backfill works technology developed schemes and technologies of salt waste allocation in underground mining workings under different mining-geological conditions using dry and hydraulic methods.

In 1991 the USSR broke up. Subsequent economic crisis decreased the volume of industrial production in the Russian Federation 2 times. Sustainable industrial growth began only after 1998. In new political and economic reality the processes of transformation of Russian economy began. A transition to the market economy and a refusal from centralized management and planning occurred. Processes of corporization and privatization of industrial enterprises took place. To enter the world market new technologies and equipment renewal were needed. And here an experience of several generations of scientists and designers of VNIIG was highly demanded. Special attention was paid to priority work directions: increase of quality and expansion of range of fertilizers which are competitive in the world and the internal markets, production of new nontraditional kinds of products which are highly demanded in Russia, CIS countries and countries outside the CIS.

In 1992 research and design institutes(head company in Saint Petersburg and the Ural branch in Perm) were incorporated and became independent companies. The institutes continued cooperation with each other.

In 1992 VNII Galurgii OJSC was established in Saint Petersburg. The specialists of VNIIG successfully solved current and problem tasks of potash, salt, sulfate and phosphate industries. In the 1990s the specialists of VNIIG and Uralkali OJSC developed and implemented a flexible technology of large-scale production of 96–98% КСL and sodium chloride of «Extra» brend using regulated vacuum-crystallization in the Fourth Berezniki plant and mine Uralkali OJSC unparalleled anywhere in the world.

The institute was the main developer of the process part of the projects of marine terminals on transshipping of potash and other kinds of mineral fertilizers in the ports of Ventspils (the beginning of the 1990s) and Saint Petersburg (the beginning of 2000), unique storage facilities for storage and transshipping of different mining-chemical raw materials as well as pits and crushing and sizing plants of building materials, warehouses of explosive materials etc. Also VNII Galurgii performed research and design works for foreign partners — Bulgaria (Mirovskiy brine field), Libya (obtaining magnesium metal and chlorine), China (production of synthetic carnallite), Island (obtaining carnallite from marine water), Egypt (obtaining magnesium oxide), Jordan and Iran (obtaining potassium sulfate), Iraq (obtaining magnesium oxide). Dekhkanabadskiy plant in Uzbekistan was built under the technology developed by VNIIG.

The task set before VNIIG — to organize industrial production of potassium sulfate (chlorine-free fertilizer) with the purpose of supply both to the internal market and to the export was successfully solved. The works on production of dressed carnallite — raw material for magnesium metal production were carried out on the whole new scientifictechnical level. VNIIG developed and implemented an unparalleled technology of drying carnallite and magnesium chloride solution in fluid-bed furnaces. It allowed to expand supplies to magnesium factories and oil producing companies.

In 2011 for the first time for 25 years in Russia a new project of the ore-dressing factory in Polovodovskiy site was started. Development and design of the new mine were performed by VNII Galurgii specialists.

VNIIG actively developed international cooperation and experience exchange with related organizations and companies, took part in the work of International fertilizer association (IFA), International Potash Institute (IPI, Switzerland), Solution mining research institute (SMRI, USA) and others.

In 2015 in accordance with the license of the Ministry of education and science of the RF for admission to carry out post graduate educational activity VNII Galurgii organized training of postgraduates on the disciplines:

- geology, exploration and development of mineral resources,

- chemical and flotation technology,

- photonics,instrument manufacture,optical and biotechnical systems and technologies.

In 1992 the Ural branch of VNIIG was also transformed into open joint stock company which got the name Ural research and development institute of halurgy (Galurgia OJSC).

By 2004 Galurgia OJSC after overcoming the economic crisis became one of the leading research and development institutes in potash industry. At that time the institute actively realized a market development strategy performing works for enterprises of Belarus, Tatarstan, Yakutia, in Gorkiy, Tula, Orenburg regions, cities: Berezniki, Solikamsk, Perm, Chaikovskiy.

In 2007 VNII Galurgii OJSC (Saint Petersburg) developed initial data for designing flotation plant of Dehkanabad potash plant in Uzbekistan using new technology. In 2010 the plant was put into operation. Galurgia JSC (Perm) carried out the design of mining complex of Dehkanabad potash plant where in the record time (2010) a mine was built and mining of sylvinite ore was started. For the first time in the world practice the deposit was opened by two inclined shafts, due to mining and geological conditions, which gives considerable advantages over the traditional opening method with vertical shafts: multiple decrease of cost and terms of construction, shaft sinking by combine method and route of transport scheme, delivery of people, materials and freights to the mine using self-propelled machines.

Project for the increase of mine capacity of Knauf Gips Novomoskovsk LLC up to 5 million tons of gypsum stone per year (2008).

Predesign work for construction of a new salt mine in Belbazhskoye deposit in Nizhniy Novgorod region (2009).

Concept of design for location of the mine site of Talitskiy ore dressing factory (2010). When choosing the location of the factory objects an analysis of six main variants of location of the mine site and three variants of location of salt tailings pile and waste storage was performed.

In 2010–2011 for Uralkali OJSC the institute carried out aprojectof Ust’-Yayvinskiymine which Galurgia OJSC developed together with the design company Institut Gipronikel LLC (surface facilities) and design-construction company Dellmann-Haniel Shaft Sinking GmbH (mine shafts). Peculiarity of this project is a conveyor transport of ore to the mill of the active Berezniki potash plant and mine 3 for the distance more than 6 km.

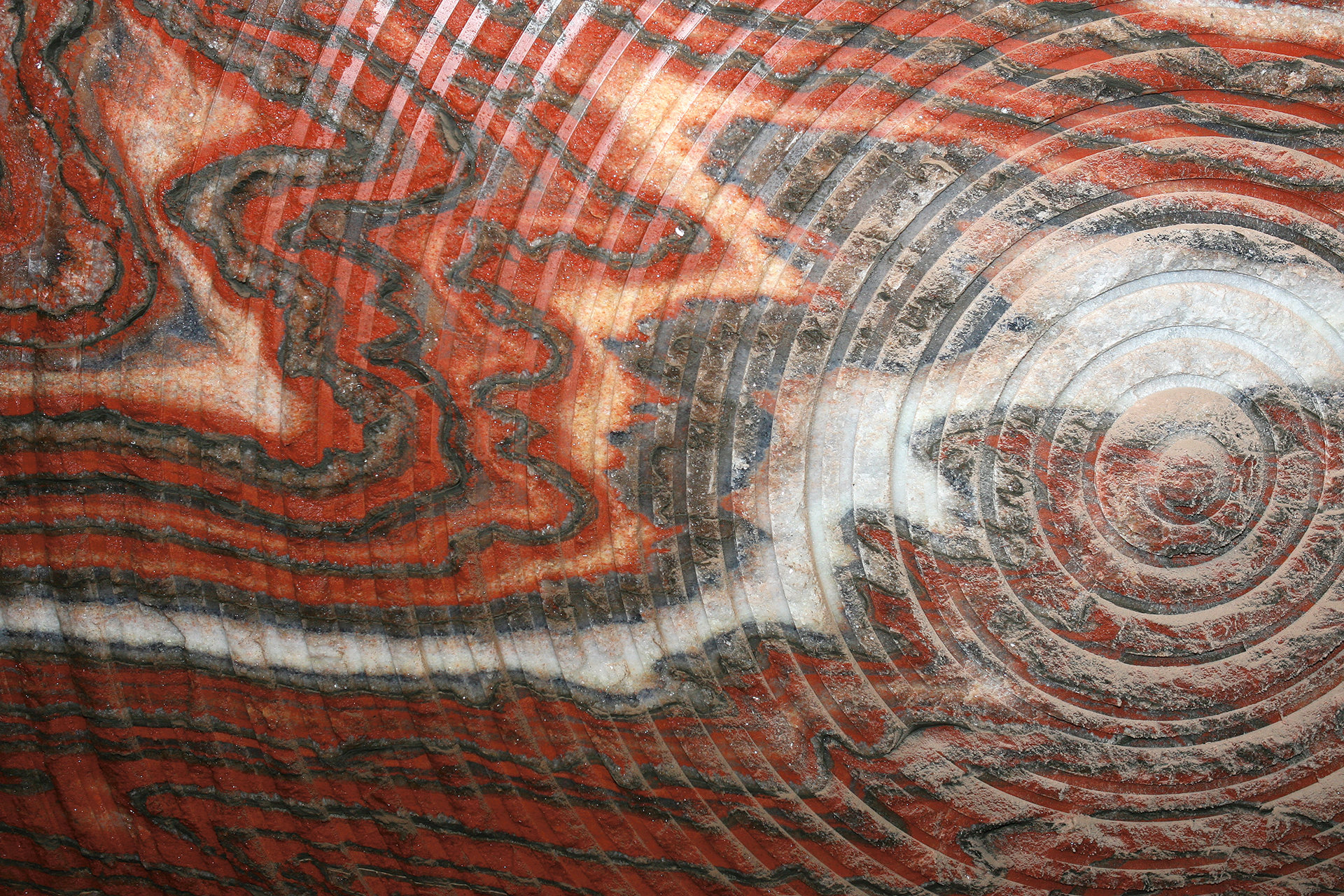

Halite A Grade

Halite B Grade

Muriate of potash, Granular Grade

In 2011 a design documentation for construction of the potash mine of Gremyachinskiy ore dressing factory in Volgograd region (Galurgia JSC, Perm) and initial data for design of the second line of the dressing plant of Gremyachinskiy ore dressing factory (VNII Galurgii OJSC, Saint Petersburg) were developed.

In 2012 Dmitriy N. Shkuratskiy became a general director of the institute who already had a large practical experience of managing a design institute. The institute took a course toward modernization of performing design and research works.

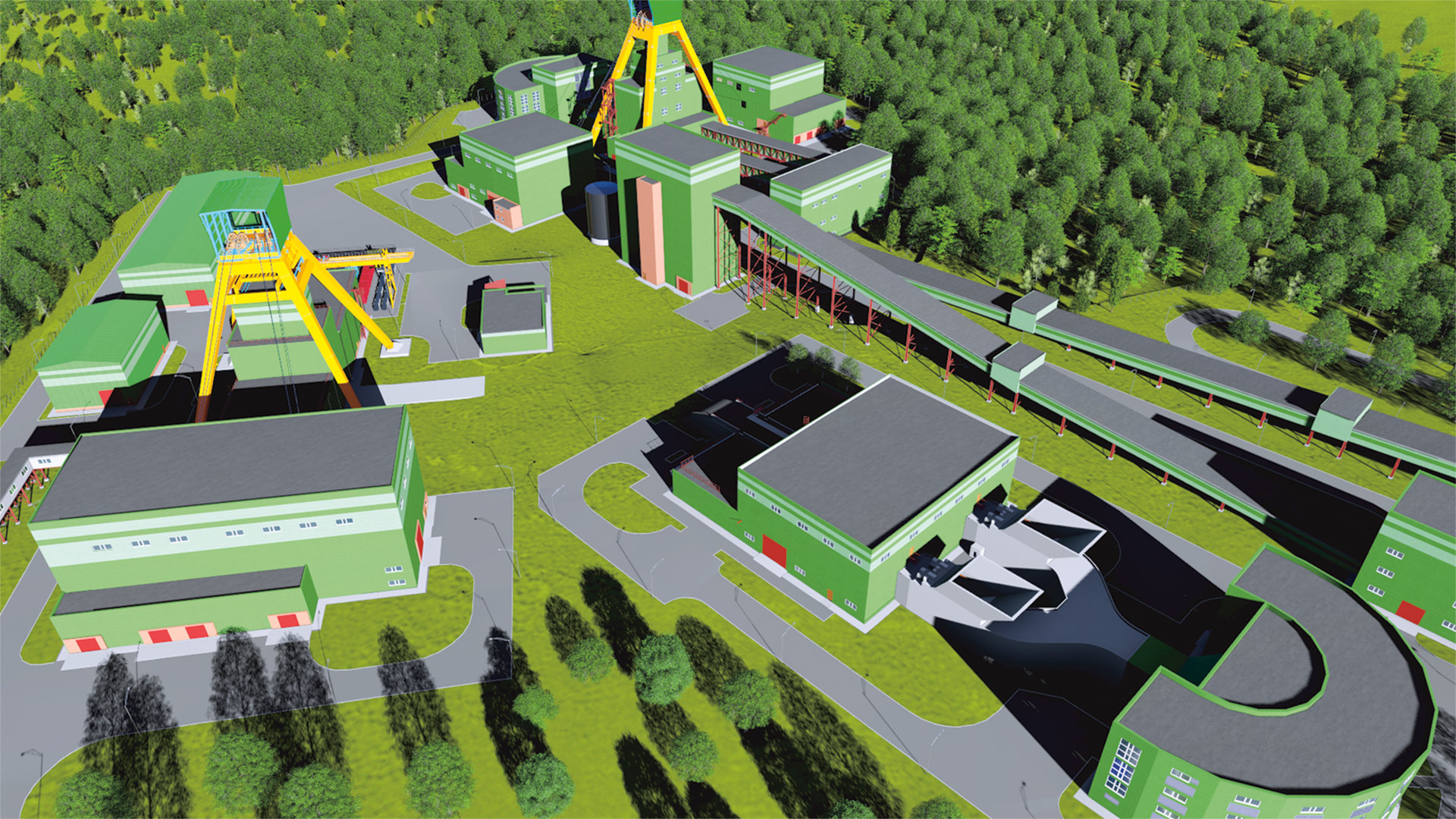

In 2014 Uralkali company opened another large-scale project — construction of Ust’-Yayvinskiy mine. Extraction volume of sylvinite ore in this object accounts for 11 million tons per year. Galurgia became the general designer of the new potash plant. During the last decade this grand project has been sequentially realized. Participation in the project required from the institute’s specialists high skills and ability to take balanced decisions.

End of 2014 became a challenge for the institute. An accident occurred in November in the Second Solikamsk mine. Managers and specialists of the institute together with production departments of Uralkali managed to prevent fast process of the mine loss and stabilization of the situation. It required a strong mobilization of the institute’s employees. There was a struggle for the mine for several months.

The institute carried out necessary research and launched a design documentation providing implementation of necessary scientific-technical solutions. As a result the accident propagation was stopped and the Second Solikamsk mine continues its operation so far.

In 2015 the institute started designing large-scale objects — ore mining and dressing plant in Talitskiy site of Verkhnekamskoye potash-magnesium salt deposit and ore mining and dressing plant of Usol’skiy potash plant.

In 2016 a transition to stratified scheme of the block preparation in Berezniki potash plant and mine 4 was realized. One of the priority projects of VNII Galurgii JSC remains the construction of the new Ust’-Yayvinskiy mine. Besides, one of the important projects of the institute is a construction of the new Yuzhny mine for mining the reserves in the southern part of the mine field of the Second Solikamsk mine.

Significant directions of the institute’s activity are design of the increase in the capacity of salt tailings piles, tailings facility, plants in Solikamsk and Berezniki: Berezniki potash plant and mine 2, Berezniki potash plant and mine 3, Berezniki potash plant and mine 4 and Solikamsk potash mine 2,3, support and putting into operation of new areas in the active mines, development of environment protection measures.

In 2016 an incorporation of Saint Petersburg VNIIG and Perm institute took place so that with common efforts they could provide solutions of technical tasks on the development of techniques for mining and processing potash ores in the enterprises of the biggest potash fertilizer producer — Uralkali PJSC.

At present the incorporated institute is moving towards the common goal combining the experience of former generations of scientists and designers. State-of-the-art design technologies suppose using highly intelligent programs and equipment. Today the institute keeps up in the application of modern means of automation of its own activity. The key point in this work is implementation of BIM technologies. Today VNII Galurgii JSC has its own constantly developing competence centre for implementation of newest technologies which has prepared more than 160 designers to perform projects using information modeling technology. Application of this technology allows not only to get full information model of the construction object but it also allows to the specialists of all disciplines to work with it simultaneously. Due to ВIМ implementation it is planned in the future to obtain a considerable effect not only in the design complex but also at the stage of construction of potash objects. The biggest current project being realized with BIM is the design of Yuzhny mine.

Achievements in the sphere of application of state of the art operation automation means have been many times confirmed by recognition of the institute as one of the BIM leaders of Russia.

Today VNII Galurgii JSC is a modern research and development institute without which the development of the mining industry of Perm krai and the whole country is hardly possible. The key priorities of the institute remain the projects of construction and reconstruction of potash enterprises.

Responding to the production requirements today the institute performs a wide range of scientific research in the field of geology and hydrogeology of potash deposits, methods of opening commercial seams, technology of potash ore mining and processing, creates new solutions on management of the waste of mining-chemical production, develops regulatory technical documentation in the specified spheres and more.

Scientific research and developments of the institute are a strong foundation of the future projects. Specialists of VNII Galurgii JSC carry out research and develop methods on mine protection against flooding, on providing safe mining works, as well as on underworking residential areas through studying geodynamic and geomechanical processes occurring in rock mass, improve technical and equipment schemes, reagent schemes of flotation and halurgic production of muriate of potash in granular and dustless form in accordance with the requirements of the world market.

Results of the scientific research are a basis for efficient design solutions on construction of new potash enterprises and reconstruction of the active ones including underground mines, pits, dressing plants.

During its whole history the institute has run active personnel and social policy. It allows to motivate employees efficiently and considerably improve labor productivity. The company offers comfortable conditions for the employees — good employee benefits (health programs — a licensed health unit, regular medical inspections, sanatorium-andhealth-resort programs, a private medical insurance program), a program for supporting young families. Today VNII Galurgii JSC employs about 600 people — 170 in Saint Petersburg, 40 in Berezniki and nearly 400 — in Perm.